Sonic Meter… Ultrasonic Cavitation Intensity Instruments

Sonic Meter offers the most reliable ultrasonic instruments for process verification of ultrasonic cavitation cleaning tanks and cell disruptors.

Sonic Meter offers the most reliable ultrasonic instruments for process verification of ultrasonic cavitation cleaning tanks and cell disruptors.

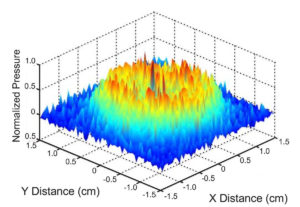

The Sonic Meter measures the ultrasonic intensity in SI units (scrub force pressure in Pascals). It uses a piezo sensing element that directly correlates with the average working pressure at a specific location. The slender 8mm probe is ideal for tank mapping of multiple locations (x, y and z). At each location an averaged reading can be recorded by the user. The total average along with the mapped pressure locations will provide the user with the capability to…

Detect transducer output loss

Detect transducer output loss- Compare tank to tank output

- Determine the most efficient location to place parts

- Achieve process control by mapping and verifying cavitation intensity over the entire tank volume

- Understand the minimum output required for maintaining process control

Ease of use…

The Sonic Meter uses an easy to navigated character display and four button membrane keypad. The meter’s narrow handheld anodized aluminum housing and user friendly interface is ideal for engineers, technicians and maintenance personnel.

Reliability…

Our meters and probes are built to superior standards in order to maintain reliable day-to-day use in harsh industrial environments.

A common failure with other cavitation/energy meters is the cracking plastic probe housings, seals and deterioration of flimsy cables and electrical connections from exposure to harsh solvents and intense pressure.

We do not use plastic parts in the construction of our probe or meter housing.

Our probes are constructed entirely  of stainless steel utilizing a sealed brazed ceramic electrical connector. We hermetically seal both ends of the probe via laser welding. Our sealed probes avoid the common failure issues associated with the bath’s solvent and the out-gassed fumes. The corrosive fumes can wreak havoc on the electrical connections. A breach in the p

of stainless steel utilizing a sealed brazed ceramic electrical connector. We hermetically seal both ends of the probe via laser welding. Our sealed probes avoid the common failure issues associated with the bath’s solvent and the out-gassed fumes. The corrosive fumes can wreak havoc on the electrical connections. A breach in the p robe’s sensing element or electrical connections will lead to corrosion, higher impedance, and a faulty signal.

robe’s sensing element or electrical connections will lead to corrosion, higher impedance, and a faulty signal.

Certification…

Our high build standards and customer commitment have made Sonic Meter the trusted leader in handheld cavitation instruments. Our meters are CE compliant with NIST traceability. We ship our meters with a calibration data sheet, certificate, and inspection checklist for traceability. All NIST traceable calibrations are controlled and maintained exclusively by Sonic Meter.

Sonic Meter Products…

Sonic Meter offers two models to choose from: The Sonic AO and the Soni Check…

Sonic AO…

Th

e Sonic AO is used for process verification and calibration of ultrasonic cleaners. It provides the operator with the options to average the intensity signal at each test location in the cavitation tank along with setting high/low intensity range indicators. The averaging function is essential for precisely verifying the tank’s average cavitation intensity at an array of locations. This level of signal processing, provided by the Sonic AO, is critical for capturing changes in intensity which could impact the cleaning process after some level of tank-transducer decay.

e Sonic AO is used for process verification and calibration of ultrasonic cleaners. It provides the operator with the options to average the intensity signal at each test location in the cavitation tank along with setting high/low intensity range indicators. The averaging function is essential for precisely verifying the tank’s average cavitation intensity at an array of locations. This level of signal processing, provided by the Sonic AO, is critical for capturing changes in intensity which could impact the cleaning process after some level of tank-transducer decay.

The Sonic AO is one of the most widely used and trusted cavitation intensity meters in the ultrasonic cleaning industry. With a wide bandwidth from a thousand Hertz up to 500 kHz output, the Sonic AO is compatible with most commercial tanks. The probe diameter is 8mm (.312″) and the length is 38cm (15″).

To view more on the specifications, click Specifications.

Click PDFs to download manuals and other useful information.

Soni Check…

The Soni Check provides reliability, simplicity and economy by integrating the probe and meter into one package. The Soni Check is used for basic functional and maintenance testing. Compared to other economical direct output (analog) meters on the market, the Soni Check provides a direct digital reading. It is designed and manufactured with the same level of quality and robustness as our Sonic AO meter but without the signal processing capability.

The user has the ability to monitor and verify basic functionality of ultrasonic cavitation tanks. The response of the Soni Check’s cavitation intensity is set at a lower rate so the user can best determine the value to record. With a wide bandwidth from a thousand Hertz up to 500 kHz output, our Soni Check cavitation intensity meter is compatible with most commercial tanks. The probe diameter is 8mm (.312″) and the length is 30cm (~12″).

Click PDFs to download manuals and other useful information.

All Sonic Meter products are manufactured and serviced in the USA.